With the program open navigate to the second tab located at the bottom of the document named standard you can also navigate to the extras tab to find additional products from mubea.

Disc spring calculate.

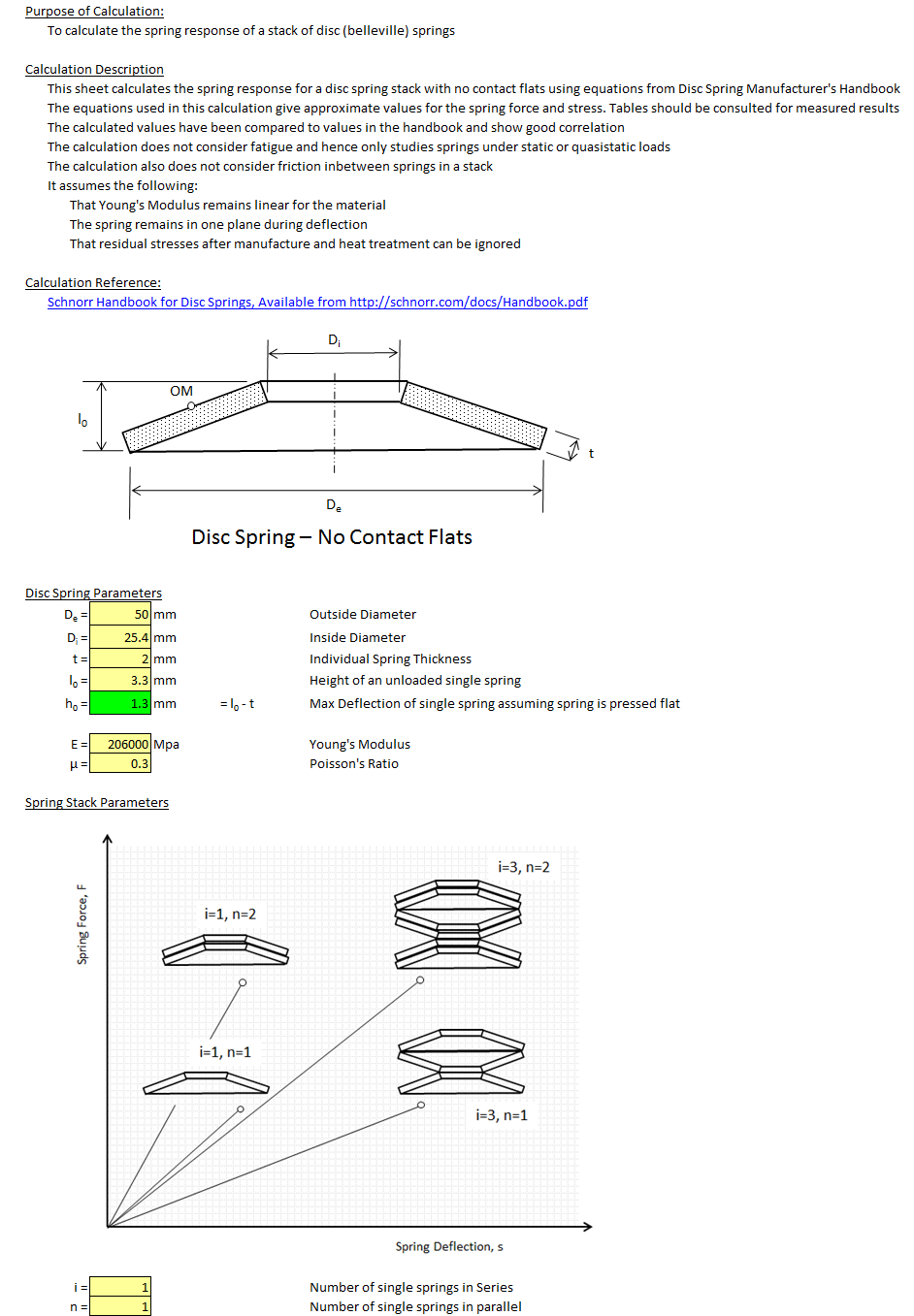

This sheet calculates the spring response for a disc spring stack with no contact flats using equations from disc spring manufacturer s handbook the equations used in this calculation give approximate values for the spring force and stress.

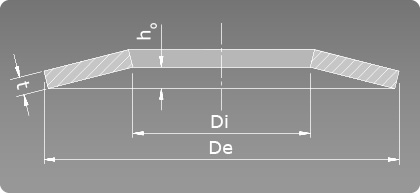

Disc springs are conical shaped washers designed to be loaded in the axial direction only.

Spring inner diameter d0 2 r0.

Original schnorr disc springs excel by.

Material selection to updated specifications.

Disc springs can be statically loaded either continuously.

What makes disc springs unique is that based on the standardized calculations of din en 16984 formerly din 2092 the deflection for a given load is predictable and the minimum life cycle can be determined.

Disc springs support a lot of dynamic processes in a skillful safe and efficient way often under extreme force and load conditions.

Disc springs can be statically loaded either continuously or intermittently or dynamically.

Long service life with dynamic load.

Download the excel version of the disc spring calculation program.

An optionally linear degressive or progressive course of the load deflection curve.

In the middle of the nineteenth century the conical shaped spring disc was invented.

Calculator for disc compression springs.

Calculator for disc springs belleville washer springs.

Storage and printout of all project data in several languages now possible.

Help with sequence of disc spring calculation and explanation of available macros.

Spring outer diameter d 2 r.

Disc spring calculation program.

Remove security settings prior to downloading to allow macros to run 2.

Belville or disc spring calculator.

Tables should be consulted for measured results the calculated values have been compared to values in the handbook and show good correlation.

This spring disc was subsequently termed a belleville washer after the name of its inventor julian f.

Modulus of elasticity e.

At a ratio of of h o t 0 5 the spring curve is nearly linear but if the ratio is 1 5 the spring will provide nearly it s full load at 50 of its stroke and then continue to deliver approximately that same load for the second half of the stroke.

The force of a disc spring does not increase linearly with the deflection but is always regressively curved.

Disc springs are conically shaped washer type components designed to be axially loaded.

How to use mubea disc spring s calculator tool.

New additional information on test values installation angles and din tolerances.

Use of high quality materials.

Precise adherence to force and dimension requirements.

For steel springs with dimensions in accordance with din 2093 formula 7 provides values which correspond closely to the measured values.