Direct laser engraving of elastomers makes the production of flexographic printing forms an entirely digital process.

Direct laser engraving of flexographic plates and cylinders.

Direct laser engraving of elastomers makes the production of flexographic printing forms an entirely digital process.

Die direkte lasergravur von flexodruckformen wird von vielen als die moderne art gesehen druckformen dafür zu machen ist der erste echte digitale weg.

Direct laser engraving of flexographic plates and cylinders.

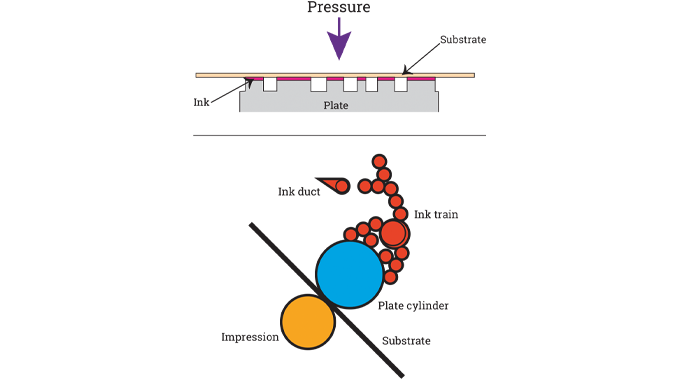

Flexographic engraving systems use single or multiple high powered co 2 lasers or fiber lasers to directly engrave continuous sleeves or plates in a single step.

Direct is better as demonstrated to perfection here.

Direct laser engraving of flexographic printing cylinders and plates has been an established process since the 1970s.

This means less manpower is needed and results in a reduced footprint.

Reducing printing form production to just two process steps laser engraving and cleaning significantly cuts the workload involved.

This means less manpower is needed and results in a reduced footprint.

This first began with the use of a carbon dioxide laser used to selectively ablate or evaporate a variety of rubber plate and sleeve materials to produce a print ready surface without the use of photography or chemicals.

Direct laser engraving of flexographic printing cylinders and plates has been an established process since the 1970s.

This first began with the use of a carbon dioxide laser used to selectively ablate or evaporate a variety of rubber plate and sleeve materials to produce a print ready surface without the use of photography or chemicals.

Reducing printing form production to just two process steps laser engraving and cleaning significantly cuts the workload involved.

Direct laser engraving of flexographic printing cylinders and plates has been an established process since the 1970s.

The laser selectively ablates the non print area of an elastomer plate or sleeve to produce a print ready surface without the.

With this process there is no integral ablation mask as.

This first began with the use of a carbon dioxide laser used to selectively ablate or evaporate a variety of rubber plate and sleeve materials to produce a print ready surface without the use of photography or chemicals.

Direct laser engraving of flexographic plates and cylinders.